| Machining range | |

| Max. swing diameter | 350mm |

| Max. machining diameter | 300mm |

| Max. machining length | 250mm |

| Max. bar through diameter | 35mm |

| Spindle | |

| Max. spindle speed(mechanical spindle) | 5000r/min |

| Spindle motor power(continous/30min) | 5.5/7.5kw |

| Spindle nose | A2-5 |

| Spindle bore | 45mm |

| Gang type tool | |

| No. of tool stations | 4 |

| Type | Gang type tool |

| Boring tool size | 25mm |

| OD tool size | 20mm*20mm |

| Travel | |

| X axis | 300mm |

| Z axis | 350mm |

| X axis rapid feed speed | 20m/min |

| Z axis rapid feed speed | 24m/min |

| Accuracy | |

| X axis bidirectional positioning accuracy | 0.008mm |

| Z axis bidirectional positioning accuracy | 0.008mm |

| X aixs repeatability positioning accuracy | 0.003mm |

| Z aixs repeatability positioning accuracy | 0.003mm |

| Size | |

| Length | 2000mm |

| Width | 1490mm |

| Height | 1610mm |

| Weight | 1845kg |

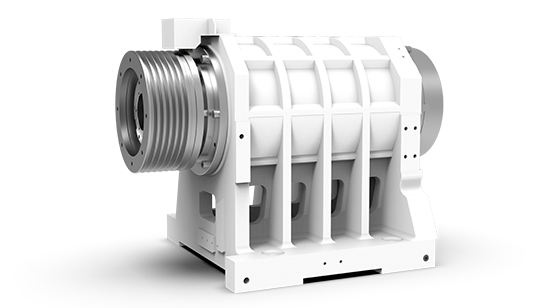

High precision & rigidity mechanical spindle

•High precision and high rigidity spindle structure

• High precision double-side dynamic balance struture

• Quantification measurement of preload

• Spindle thermal equilibrium experiment

• Dynamic precision test

• High speed and high precision control

It adopts GSKLink industrial Ethernet bus technology. The highest running speed is 100m/min. Gr-l series servo devices and servo motors with high resolution absolute encoders are standard equipped, which can be connected with grating scale, reluctance, magnetic grid, circular grating encoders, etc., to realize full closed-loop control of feeding axis and high-precision Cs axis control.

• Simple and fast system debugging guide

This function can list the parameters to be debugged according to the debugging steps, functional modules and other projects, so as to simplify the debugging process of machine tools.

• Examine intelligently/Diagnosis technology

It has the functions, including grammar check, track preview, machine tool fault diagnosis, as well as operation log, alarm log and machining log, which are convenient for program verification, fault diagnosis and maintenance.

• It supports remote monitor and diagnosis

Based on the Ethernet LAN interface, it can realize the remote monitor and fault diagnosis to CNC lathe, as well as the collection and analysis of reliable data, including the uploading and downloading data of machining doc, parameter doc, and tool deviation, etc., which truly realize the function of remote monitor. Besides, it supports FTP communication transfer protocol.