| Machining range | |

| Max. swing diameter | 620mm |

| Max. machining diameter | 330mm |

| Max. machining length (Two chuck support) | 550mm |

| Max. distance from main spindle face to second spindle face | 880mm |

| Main Spindle | |

| Chuck size | 8 inch |

| Max. spindle speed | 5000r/min |

| Spindle motor power(continous/30min) | 11/15kw |

| Spindle nose | A2-6 |

| Spindle bore | 62mm |

| Max. bar through diameter | 51mm |

| Second Spindle | |

| Size size | 8 inch |

| Max. spindle speed | 5000r/min |

| Spindle motor power(continous/30min) | 11/15kw |

| Spindle nose | A2-6 |

| Spindle bore | 62mm |

| Max. bar through diameter | 51mm |

| Upper turret | |

| No. of tool stations | 12 |

| Tool change time | 0.2s |

| Milling axis power | 3.7KW |

| Milling axis speed | 5000r/min |

| Boring tool size | 40mm |

| OD tool size | 25mm*25mm |

| Lower turret | |

| No. of tool stations | 12 |

| Tool change time | 0.2s |

| Boring tool size | 40mm |

| OD tool size | 25mm*25mm |

| Travel | |

| X1/X2 axis | 225mm |

| Z1/Z2 axis | 700/650mm |

| Y1 axis | ±50mm |

| W axis | 630mm |

| X1/X2 axis rapid feed speed | 30/30m/min |

| Z1/Z2 axis rapid feed speed | 30/30m/min |

| Y1 axis rapid feed speed | 20m/min |

| W axis rapid feed speed | 30m/min |

| Size | |

| Length | 3290mm |

| Width | 2200mm |

| Height | 241mm |

| Weight | 11500kg |

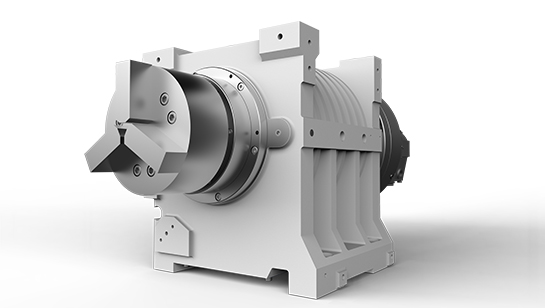

High precision & rigidity synchronous servo direct drive built in motor spindle

• The front bearing adopts high precision conical double roller bearing & ball bearing and row angular contact ball bearing, which can bear a greater axial load, to realize heavy cutting and to replace the grinding.

• Low speed and high torque, high outout efficiency.

• Spindle driven by built-in motor directly, realize “zero transmission”. Compact design, light weight, low vibration, low thermal deformation. With characteristics of high torque by low speed and high speed. High precision on both dynamic and static, and high stability.

• High precision, high rigidity, high stability, high efficiency.

• Low vibration, low noise, good balance, good thermal characteristics.

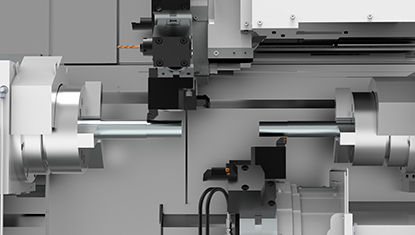

High precision & rigidity servo hydraulic live turret

• It adopts the basic structure with servo motor indexing, arc gear tooth positioning, hydraulic locking.

• Turret index without lifting, reduce the tool change movement, avoid scraps & coolant entering inside of the positioning accuracy.

• The toothed disk is tightly locked by hydraulic force to ensure that the 7Mpa high pressure cooling water still maintains enough tension when passing through the turret.

Parallel compound machining

• Dual workspace mode

• Double turret parallel working mode

• Slender shaft workpiece processing

• Excellent performance

SIEMENS828D has features such as 80 bit floating point nanometer calculation accuracy, ISO programming language compiler and compatibility with various programming languages, SMS function, numerical control simulation, animation support and so on.

• Intelligent programming

This PC version CAD Reader can support to transform Contour and location models on PC form the DXF format to the one which control system can recognize. It can continue to edit these profiles in the contour editor in control system. With the help of SinuTrain, it can program parts on a PC which is like operating SIEMENS 828D on the machine.

• Rugged and Maintenance free

SIEMENS 828D system adopts die-cast magnesium operate panel fronts, the panel-base CNC design with just a few interfaces, as well as high degree of protection, reliable operation in harsh environments. SIEMENS 828D has no fan, no hard disk, and an NV-RAM memory without a buffer battery, which makes it a completely maintenance-free CNC.

• User-friendly

SIEMENS 828D system uses a full CNC keyboard with short stroke keysand a high resolution 10.4" TFT color display /15.6" touch display, extremely simple to operate. Equipped with USB, CF card (for 10.4")and RJ45 interfaces at the operator panel front, CNC data is quickly and easily transferred.